Blackstrap molasses rum recipe

A multi-use recipe for different types of rums.Pot still

- flavors

- faster runs

- easy operation

Difficulity

Costs

Aging

Quality

The goal of this recipe is to make it as versatile as possible. It has many optional ingredients and instructions that can be included or ignored based off your experience, equipment and ingredients available. This recipe should be capable of making a overall high quality light, medium or dark rum as well as spiced or flavored depending on the flavor profile you are trying to achieve.

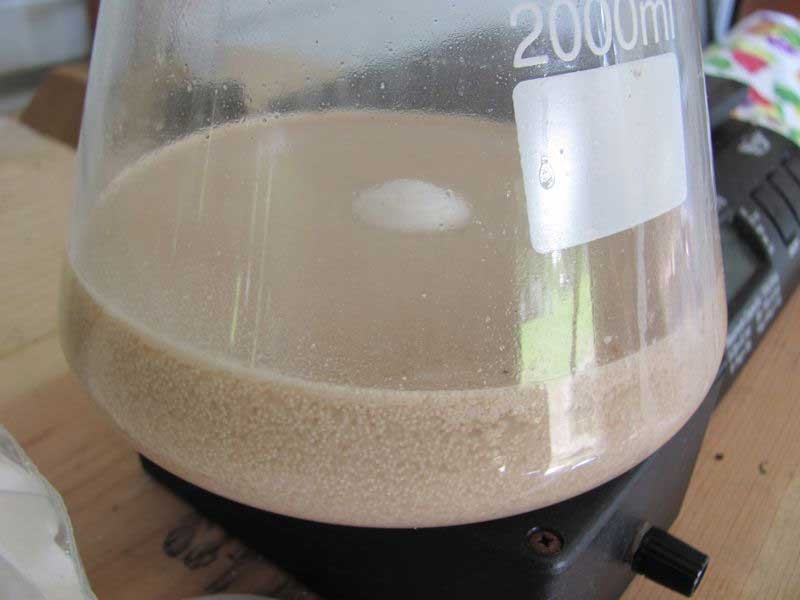

When transferring to your boiler it is beneficial to use a siphon. Boiling the yeast and the solid material from the molasses can add unwanted flavoring to your final product or these components can get burned and making cleaning time consuming. When siphoning keep the siphon about 2 inches from the bottom (or further if not using a proper siphoning tool).

For an optimal run it will be beneficial to siphon down to the last 2 or 3 inches if using a proper siphoning tool. Rack this last two inches into a secondary container. Using a small 1 gallon container works well as you can place this in the fridge to help separate the yeast. Wait several hours for this to separate and siphon off the remaining wash or save it to use in your next run. The yeast can be reused in your next run, or converted into yeast trub.

Yeast trub (the sediment at the bottom of the fermenter) can be re-used several times in fermenting or it can be converted into a yeast nutrient. See the yeast trub section above for more details.

Parts of this recipe were inspired by several recipes made over the years.

Pugirum rum recipe

Buccaneer Bob's

The highest costs for rum for many people will be the molasses. In some countries molasses can be very inexpensive, but in the US and Europe it can be difficult to find feed grade molasses that is safe to use and not expensive. Some people may decide to go with food grade molasses which gets very expensive very fast, or dried molasses which can be difficult to find but costs less than food grade store bought molasses.

Brown sugar generally costs twice as much or more as white sugar, so always check the prices in your grocery store to see if you can find it while on sale.

Flavoring your rum can start to get expensive depending on the quality of ingredients and quantity. Many people choose to use for example vanilla beans or pure vanilla extract. Personally I go inexpensive and buy imitation vanilla which does the job of flavoring.

The biggest difficulty like cost is the molasses. Finding safe to use feed grade blackstrap molasses can be very difficult. If you’re in a city you may need to research places within a reasonable distance to drive to. Also many stores that sell feed grade molasses simply don’t know the contents of the molasses which can contain preservatives (propionic acid) , anti-freeze components (Propylene glycol) , pesticides, vegetable fats, vitamins or other stuff you don’t want. If you can find it land-o-lakes makes a great and safe feed grade molasses that distillers feel is safe and is often suggested.

The other difficulty with this recipe depends on the many available options such as the use of dunder and rum oils. The most basic use of the recipe is really quite easy but it can start to get more difficult, time consuming and require additional equipment to do well and properly.

For specific aging and flavoring techniques please see our additional rum recipes. All our rum recipes use this recipe as the base process for the rum and specifically discuss the different flavoring techniques and ingredients.

This is by far my favorite rum recipe. The overall quality of the rum when following just the basic recipe and not including any of the optional steps will turn into a wonderful product once aged and flavored. I cannot say how good the quality is for light rums because personally I’ve never been a fan of light rums. But the quality of the rum after a few weeks of aging on oak and or with flavoring added can be as good as store bought products. My favorite spirit I have made is a spiced rum based off this recipe, and everything who has tasted it have been shocked at the quality.